Powder coating lines

Design, delivery, installation, commissioning.

Products: metal, ceramics, glass, MDF.

Liquid painting lines

Design, delivery, installation, commissioning.

Products: metal, ceramics, glass, MDF.

Pre-treatment unit before painting

1. Units for chemical technologies for preparation and treatment of ferrous and non-ferrous metal surfaces:

- For environmental phosphate-free coatings

- For interoperative degreasing and passivation

- For conventional chemical coatings: - Fe phosphating, Zn phosphating

- For zirconium chemical coatings

- For conversion coatings

- For nanoceramic coatings

- For multimetal coatings-processing with one technology of ferrous and non-ferrous metals

- Replacing old technologies Anaphoresis and Cataphoresis with new technologies requiring less investment and lower production costs.

2. The units for interoperative degreasing and surface preparation.

They are used for degreasing and passivation between different technological operations:

- After plasma and laser cutting of blanks

- After lathe and milling operations

- After welding

- After hydraulic test before assembly

- After punching and deep drawing

- Before assembly

- Before painting

In most cases, one degreasing is enough before painting, but some specific technological requirements and restrictions require the use of interoperable degreasing in combination with passivation to provide temporary corrosion protection.

3. Types of energy sources - electricity, diesel and natural gas.

4. Combined units - immersion sections and jet sections are used. The choice depends on the chosen technology.

5. Units type: one process - one tunnel. With this type of unit, the number of tunnels or baths is the same as the number of technological processes. The parts are hung on a hanging conveyor or placed on a belt conveyor and pass through the individual tunnels at a constant speed. A separate chemical treatment is performed in each tunnel.

6. Units type: One tunnel / bath - several processes with different solutions. This model has advantages - it takes less space, but there are also disadvantages - increased material consumption.

Powder coating cabin

Cabins with cyclones

Cabins with built-in filters

Stainless steel cabins

Plastic cabins

Cabins for hand painting

Cabs for automatic painting

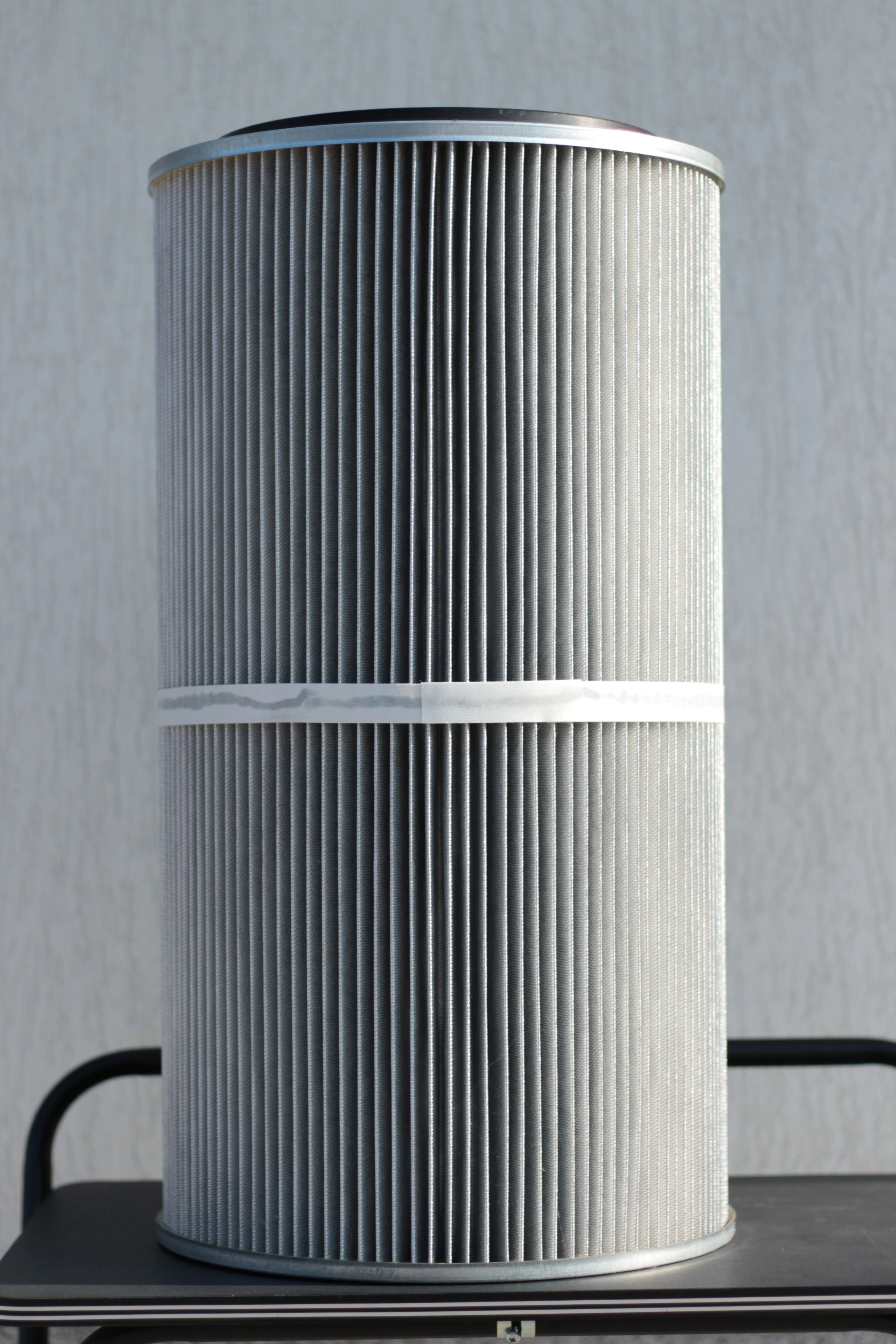

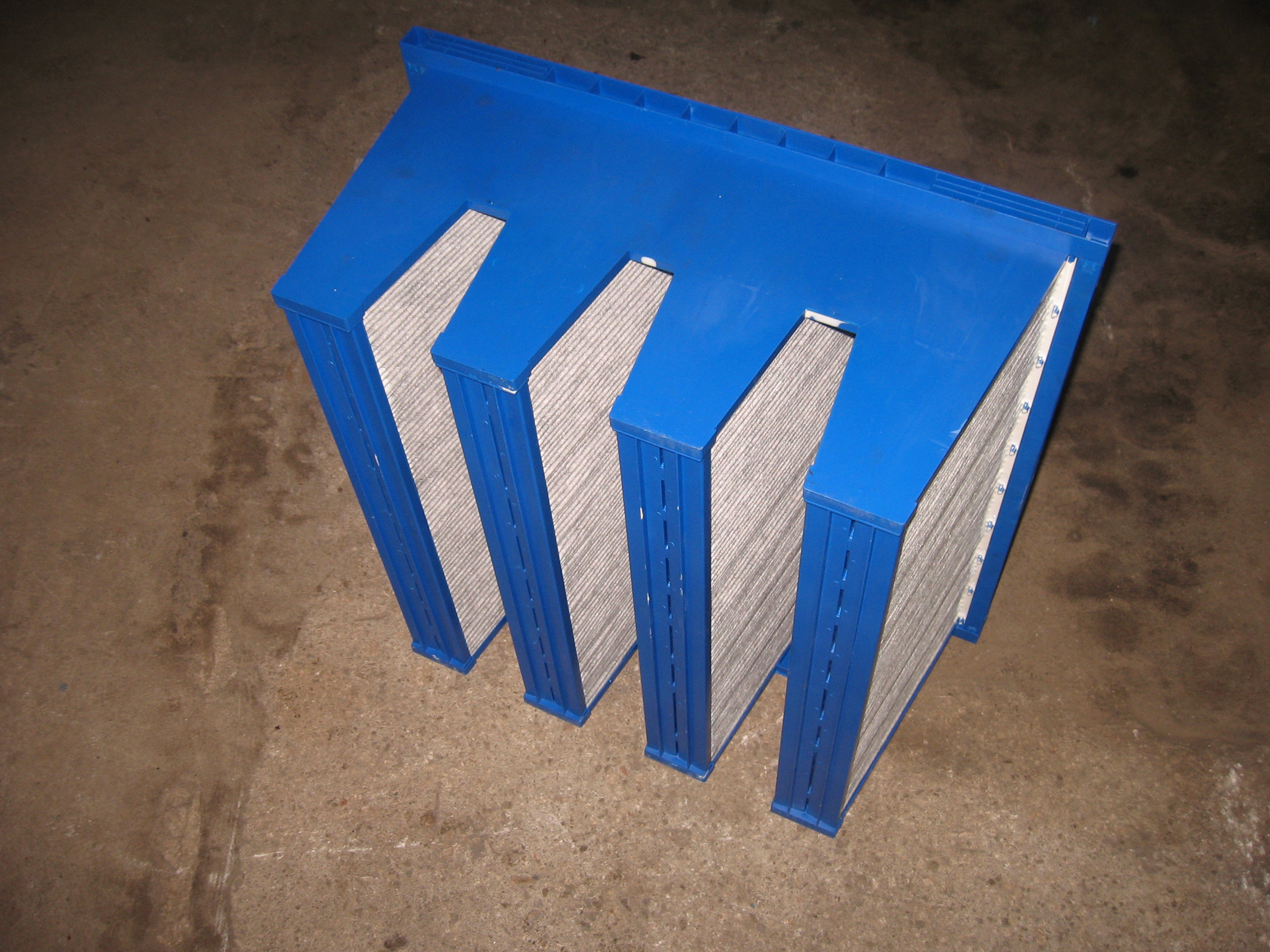

Powder filter systems

Cyclones and filter systems with automatic regeneration of cartridge filters.

Application: workshops for powder painting, powder enameling, blasting - with crumbs, glass beads, dusty environment in woodworking and furniture workshops.

Manipulators for painting

For powder coating

For powder enameling

For liquid painting

Conveyors

Hand conveyors

Hanging conveyors - automatic

Floor conveyors

Conveyors - POWER&FREE

Industrial oven

Energy source: electricity, natural gas, diesel.

Insulation with mineral wool - 150 mm.

Internal ventilation - height and length.

Infrared heaters when using electricity.

Heat exchange chamber when using natural gas and diesel.

Accessories and auxiliary equipment

Powder filters for powder painting and enameling.

Dry filters for liquid painting.

Carbon filters to remove toxic odors.