Conveyor Systems

TPP – Tehnoprojektplast designs, delivers, and installs industrial conveyor systems for over 25 years in Bulgaria and abroad.

Thanks to our long-term experience and partnerships with leading manufacturers, we offer optimal solutions for automated and semi-automated transport of parts and products – from lightweight components to items exceeding 100 kg.

We have successfully completed numerous projects, helping our clients increase productivity, optimize workflow, and meet the specific requirements of different industries.

Description and Application

Our conveyor systems are integrated solutions for automated or semi-automated transport of parts and products within production processes.

They improve productivity, optimize workflow, and can be easily adapted to the specific needs of various industries – from mechanical engineering and automotive production to food processing and logistics.

The systems we provide ensure a continuous and controlled material flow between process stages, reducing downtime, minimizing errors, and lowering the physical strain on personnel.

Our conveyors – whether in-house manufactured or supplied from trusted international partners – are built from standard modular elements, assembled with bolt connections (no welding required).

This modular concept ensures flexibility, allowing for easy system expansion, relocation, or adaptation whenever production requirements change.

High Productivity

-

Automated transport enables fast and efficient movement of parts between operations.

-

Significant reduction in downtime and increased production capacity.

Cost Efficiency

-

Achieve higher productivity with less personnel.

-

Reduced need for manual handling of parts.

-

Minimized losses and transport-related errors.

Flexibility and Adaptability

-

Designed and customized according to client-specific needs.

-

Integration with robotic systems and automated production lines.

Optimal Use of Production Space

-

Compact design and modular layout allow for efficient use of available floor area.

Safety

-

Reduced risk of workplace accidents related to manual handling of heavy or bulky loads.

Fields of Application

Conveyor systems are widely used across various industrial sectors, including:

-

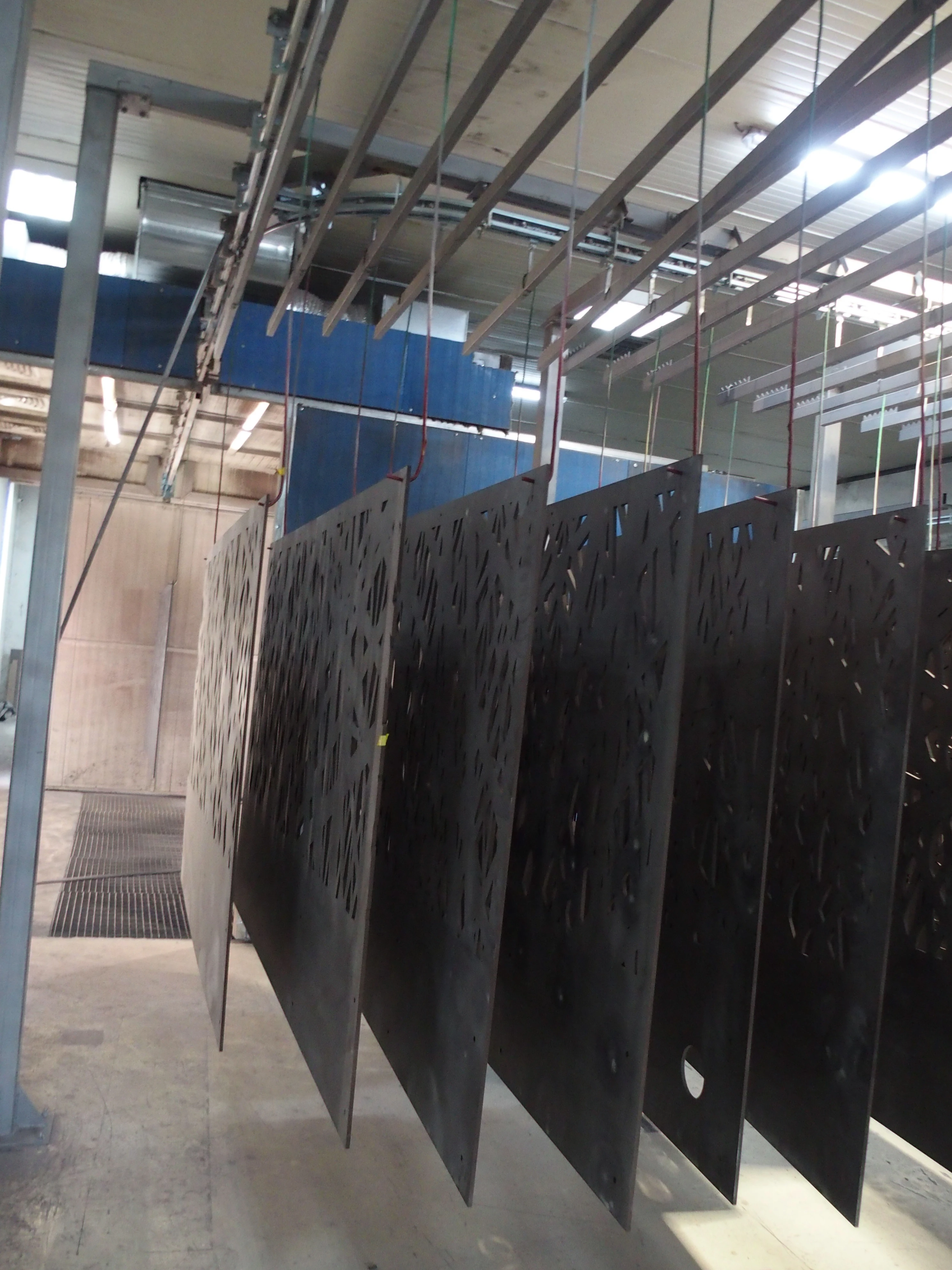

Production lines for multiple technological operations in mechanical engineering and manufacturing – from surface treatment and painting to assembly, packaging, inspection, and more.

-

Automotive industry – tailored conveyor solutions for precise part handling between workstations and painting chambers, ensuring smooth product transfer.

-

Food processing industry – hygienic, non-toxic systems designed for safe and reliable operation.

-

Other industries – modular design allows easy implementation in different applications, ensuring flexibility and efficiency.

Types of Conveyor Systems

-

Chain conveyors – for heavy goods or parts with non-standard shapes.

-

Belt and roller conveyors – universal solutions for a wide range of products.

-

Spiral and vertical conveyors – for upward transport in limited spaces (commonly used in the food and beverage industry).

Our Services Include

-

- Product and process analysis based on client requirements

-

Concept design and technical proposal (upon request)

-

Equipment supply

-

Installation, commissioning, and personnel training