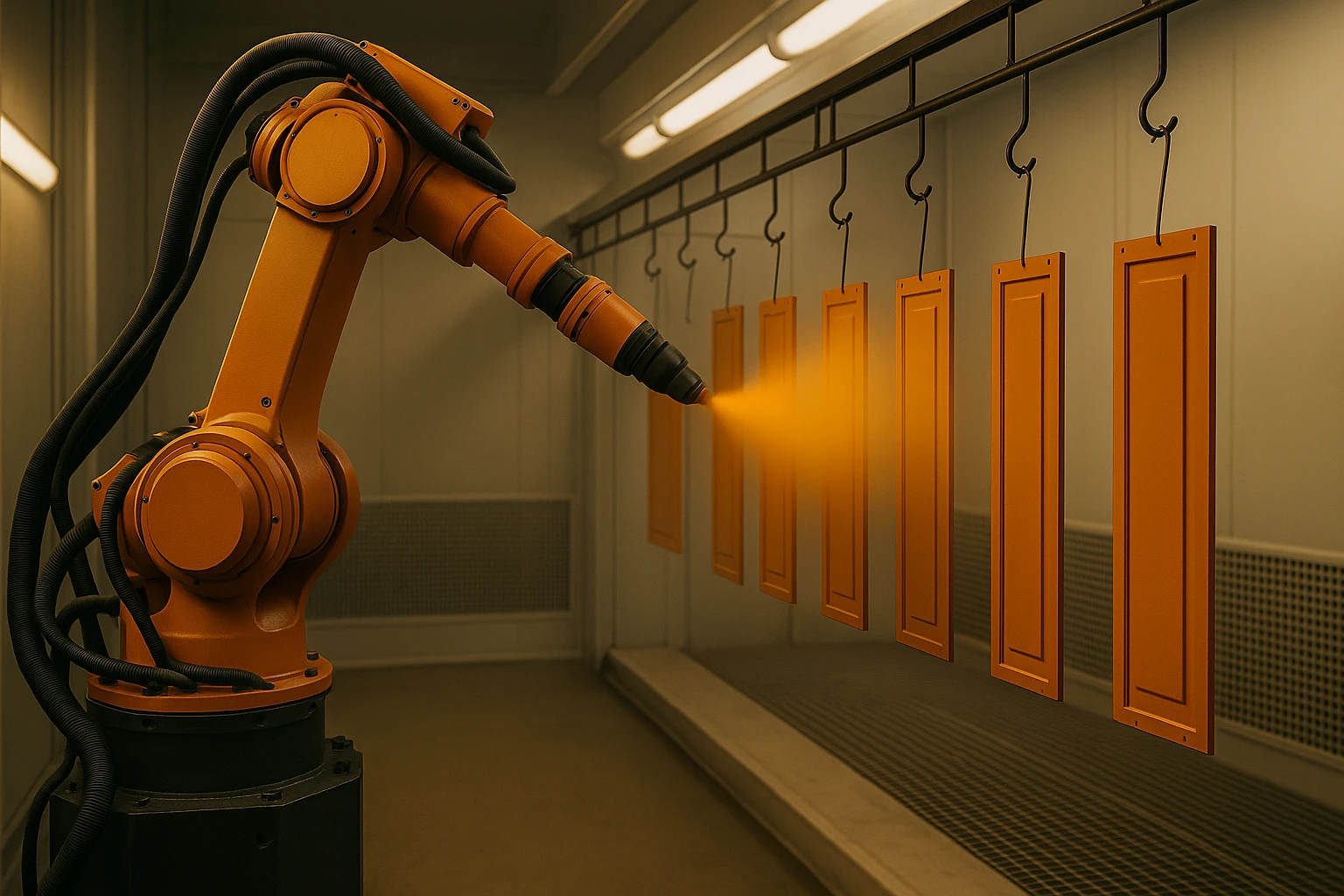

Industrial Painting Robots

Overview and Advantages

Industrial painting robots are a key element of modern manufacturing, where automation, efficiency, and cost reduction play a crucial role.

Their implementation allows for:

-

High-quality coating with consistent results and no human error

-

Significant increase in productivity for large-scale production

-

Optimized labor and material costs

-

Enhanced competitiveness through access to new markets enabled by advanced technologies

-

Flexibility in programming, offered by most modern robotic systems

Why Choose Industrial Painting Robots?

Six-axis robots are ideal for processing complex-shaped parts that require precision and repeatability.

They are a cost-effective solution for companies aiming for long-term development and sustainable production.

Our Approach:

When selecting a painting robot, it is essential to make an accurate assessment of the production needs.

Our team always starts with a detailed consultation to determine:

-

Production volumes

-

Complexity of the parts

-

Automation and integration requirements

After clarifying all technical parameters and the required level of automation, we propose an optimal solution fully tailored to your production process.

Key Benefits of Robotic Painting Systems

-

- High quality and uniform coating

-

Reduced labor and material costs

-

Safe and controlled working environment

-

Flexibility and easy integration into automated production lines

-

Fast return on investment